Tubular pasteurizer for WPA-9 juice

Tubular pasteurizer for WPA-9 juice

Contact us for price

Location:Siemyśl, Poland

Description

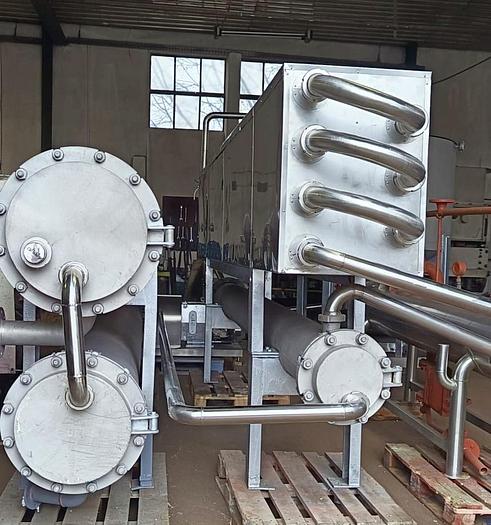

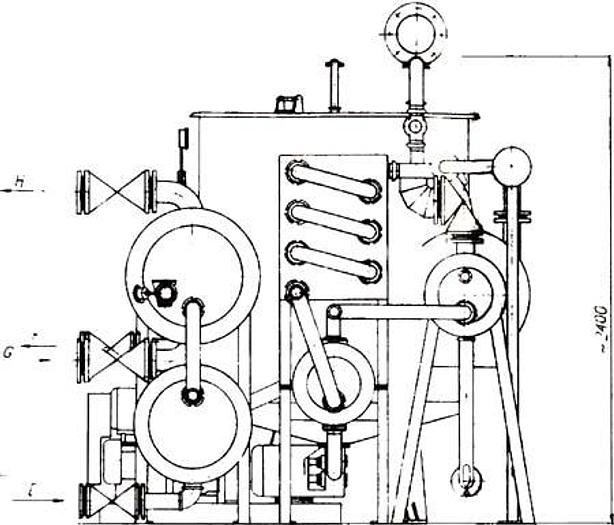

Tubular pasteurizer for juice WPA-9 It is intended for the thermal treatment of fruit juices, unfiltered musts, after pressing.

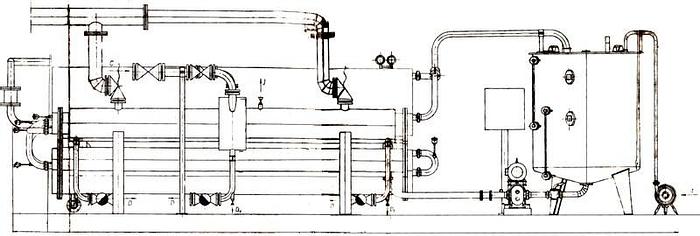

Working parts made stainless steel, others carbon steel. Dimensions: - Total length - 6,400 mm; - Total width - 3,900 mm; - Total height - 2,650 mm. Technical data: - Product pressure of exchanger I and IV - up to 0.8 MPa; - Steam pressure of exchanger II - 0.3 MPa; - Water pressure - exchanger III and IV - 0.45 MPa; - Heat exchanger steam demand - 1,330 kg/h; - Water demand - exchanger III and IV - 19 m3/h; - Exchanger I and II - pipe size:

- diameter 25 mm,

- thickness 1.24 mm,

- length - 4,280 mm;

- 78 pcs - exchange surface 28.1 m²; - Exchanger III and IV - pipe size:

- diameter 33 mm,

- thickness 1.5 mm,

- length - 4.580 mm;

- 189 pcs - area exchanges 89.7 m²; - Holder - 76x3x4.900 mm - 12 pcs - exchange area 14.3 m²; - Total capacity of the tank - 2,470 dm3; - Exchanger II: heating space - 272 l; - Internal space - 82 l; - Product capacity in circulation - 1,250 l; - Nominal capacity - 10,000 kg/h; - Product pressure - 8 bar; - Pasteurization temperature 90-120 °C; - First stage of pro cooling - Steam demand - heat exchanger II - 950 kg/h; - Steam pressure - 3 bar; - Water demand at 15 °C (heat exchanger III) - 22 m³/h; - Water pressure - 4.5 bar; - Amount of heat exchanged in heat exchanger IV - 426,500 kcal/h; - Product holding time - 1 min .; - Installed power - 7.7 kW (feeding pump - 2.2 kW, forcing pump - 5.5 kW); - Net weight - 5,700 kg; - Weight during operation - 9,500 kg;

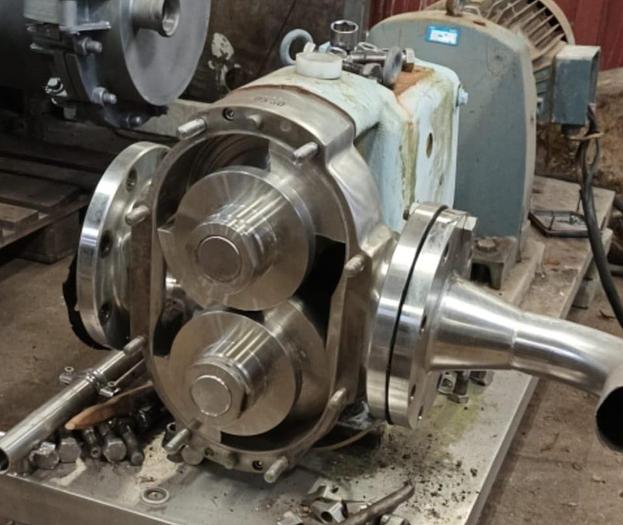

- Product circulation through all sterization and cooling phases forced by the Waukesha pump. The basic phases of the pasteurizer's operation include:

- Feeding the product into the supply tank; - Pre-heating the product in the heat exchanger I to a temperature

of approx. 50 ° C using the product's heat heated; - Heating the product to the pasteurization temperature, i.e. 95-100 °C

(the possibility of achieving a higher temperature even up to 120 °C)

in heat exchanger II; - Keeping the product at pasteurization temperature for

approx. 1 min. in the detainee; - Initial cooling of the product to a temperature of approx. 60 °C by

transferring heat to the input product in the exchanger heat I; - Further cooling of the product to a temperature of approx. 30 °C

in the heat exchanger III, cooled with water; - Final cooling of the product to a temperature of 20-5 °C in a heat

exchanger IV cooled with ice water, brine or glycol. The final product is pasteurized and cooled to 30-5 °C, the product

is directed to the next part of the process technological. Description of WPA-9 pasteurizer operation: The product to be pasteurized is pumped into the feed tank. Product level in the supply tank is held by the level sensors that control the operation of the pump so that it cannot be lower than the assumed minimum level and not higher than the assumed maximum level. Product level observation in the supply tank is possible in the installed liquid level gauges. After opening the valve, the product is fed to the pasteurizer by means of a pump with adjustable capacity as required range. The amount of product fed to the pasteurizer is recorded on a flow meter installed on the line supplying the product to the heat exchanger I, where it is preheated from the initial temperature approx. 15 °C to approx. 50 °C. In heat exchanger I, heat is exchanged between the product cooled down pasteurization and the input product prior to pasteurization. After initial heating, the product enters heat exchanger II, where it is heated to temperature pasteurization, i.e. approx. 90-100 °C (it is possible to obtain a higher pasteurization temperature, if necessary). The heating medium is saturated steam with a pressure of 3 bar, fed through a pipeline to the inter-pipe space via valves. The product, heated to the pasteurization temperature, is directed to a holding cell where it is kept in temperature of pasteurization without heat input for approx. 1 minute, then it is directed to cooling. The first cooling step takes place in the heat exchanger and the cooled input product in which the product undergoes cooling down to a temperature of approx. 60 °C. The second stage of cooling takes place in the heat exchanger III cooled with cold water supplied and discharged through valve in which the product is cooled to a temperature of approx. 30 °C. In the third, and last, stage of cooling, which takes place in the heat exchanger IV cooled with ice water, brine or with glycol supplied and discharged through the valve, the product is cooled down to the temperature of 20-5 °C and the product is collected is to continue the technological process through the valve. In the event of disturbances in the reception of the product from the pasteurizer, it is possible to maintain the circulation of the product in the system closed: heat exchanger I, heat exchanger II, supply tank through the return circuit. For this purpose the three-way valve must be opened so that it acts on the return circuit. After removing the disturbance in reception, set the valve so that to put the product into the complete cycle of the pasteurizer.

Specifications

| Model | "WPA-9" |

| Condition | Used |

| Stock Number | 209.5 |